by V.Ganapathy

The

example shows how one can use the HRSG simulation methods to improve the

efficiency of a system.

problem:

A gas turbine HRSG is required to generate a desired

quantity of High Pressure steam and maximize the Low pressure steam. The

question is what should be the HRSG configuration.

data:

exhaust

flow=500,000 lb/h

exhaust

temperature=900 F

gas

analysis:% vol CO2=3,h2O=7,N2=75,O2=15

HP

steam: 31,500 lb/h at 600 psig,600 F

LP

steam: maximum in the unfired mode at 150 psig sat.

feed

water=230 F

assume

heat loss=1 %

Solution:

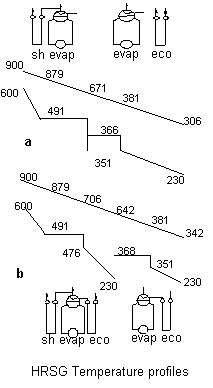

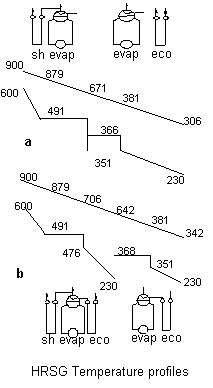

The

HRSGS program was used to simulate different configurations. Two are presented

below. In Option a,there are three modules. HP superheater with evaporator,LP evaporator,follwed by the common

economizer.The HP pinch point was selected to give the desired steam flow,while low pinch and approach points were used for the LP section to maximize the LP steam flow.

In option b,the HP section has its own superheater,evaporator and economizer,followed by the LP section with its own evaporator and economizer. Tables a and b show the results from the

program.

Table showing results of Option a

| surface |

gas in |

gas out |

wat in |

stm out |

duty |

press |

flow |

% stm |

pinch |

approch |

| suph |

900 |

879 |

491 |

600 |

2.72 |

615 |

31759 |

100 |

- |

- |

| evap 1 |

879 |

671 |

351 |

491 |

28.00 |

630 |

31759 |

100 |

180 |

140 |

| evap 2 |

671 |

381 |

351 |

366 |

37.93 |

165 |

43453 |

100 |

15 |

15 |

| econ |

381 |

306 |

230 |

351 |

9.51 |

650 |

76716 |

0 |

- |

- |

[units:

temperatures-F,duty-MM Btu/h,pressure-psia,flow-lb/h]

Table showing results of Option b

| surface |

gas in |

gas out |

wat in |

stm out |

duty |

press |

flow |

% stm |

pinch |

approch |

| suph |

900 |

879 |

491 |

600 |

2.70 |

615 |

31468 |

100 |

- |

- |

| evap 1 |

879 |

706 |

476 |

491 |

23.36 |

630 |

31468 |

100 |

215 |

15 |

| eco 1 |

706 |

642 |

230 |

476 |

8.38 |

640 |

32097 |

0 |

- |

- |

| evap 2 |

642 |

381 |

351 |

366 |

34.09 |

165 |

39050 |

100 |

15 |

15 |

| eco 2 |

381 |

342 |

230 |

351 |

4.95 |

175 |

39831 |

0 |

- |

- |

|

|

ANALYSIS

It can be seen that in option a,we have a larger

heat sink in the economizer feeding the two modules. This economizer handles the water flow equivalent of the two evaporators and hence is able to pull down the gas temperature from LP evaporator exit to a much lower value.In option b,the

heat sink is not as large,as the economizer handles only the LP flow.Hence the exit gas temperature in option a is lower

and thus more energy is recovered. Thus using the HRSGS program,one can simulate

different configurations,modules and rearrange their locations to maximize energy recovery.

Click here for more information

on HRSGS program

Click here for more information

on HRSGS program

V.Ganapathy's

Home page

V.Ganapathy's

Home page

Generating

steam efficiently in cogeneration plants

Generating

steam efficiently in cogeneration plants

Understanding HRSG temperature Profiles

Understanding HRSG temperature Profiles

Click here for more information

on HRSGS program

Click here for more information

on HRSGS program V.Ganapathy's

Home page

V.Ganapathy's

Home page

Generating

steam efficiently in cogeneration plants

Generating

steam efficiently in cogeneration plants

Understanding HRSG temperature Profiles

Understanding HRSG temperature Profiles