Heat

Recovery in Kalina Cycle V.Ganapathy

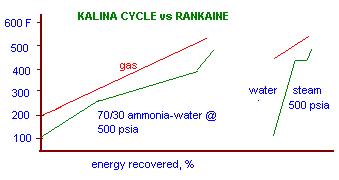

The

Kalina cycle is a new concept in heat recovery and power generation,which

uses a mixture of 70% ammonia-30% water as the working fluid with the potential

of significant efficiency gains over the conventional Rankaine cycle.Basically

this concept is suitable for medium to low gas temperature heat recovery

systems with

gas inlet temperatures in the range of 400 to 1000 F,offering more gains

(over Rankaine cycle) as the gas temperature decreases.

Gas

turbine based combined cycles using this concept have 2-3 % higher efficiency

over multi-pressure combined cycle plants using steam/water as the working

fluid. In low gas temperature heat recovery systems such as diesel engine

exhaust or fired heater exhaust,the energy recovered from the hot gas stream

is more significant and Kalina cycle output increases by 20-30 %.The

main reason for the improvement is that the boiling of ammonia-water mixture

occurs over a range of temperatures,unlike steam and hence the amount of

energy recovered from the gas stream is much higher. See Figure below,where

a 550 F gas temperature source is shown with say a cold end fluid temperature

of 100 F. 70 % ammonia-water mixture at 500 psia by virtue of its varying

boiling point,is able to "match" or run parallel to the gas temperature

line while recovering energy and hence the exit gas temperature can be

as low as 200 F.The steam-water mixture at 500 psia,on the other hand,due

to pinch,approach point limitations and a constant boiling point of 467

F,cannot cool the gases below about 500 F.Only about 15-20 % of the energy

is recovered,compared to 100% in Kalina cycle.This can also be easily be

seen using the HRSG simulation software for gas turbine-steam systems developed

by the author(see my Homepage). Hence a lot of energy is wasted. By decreasing

the steam pressure,more energy could be recovered;however,the average fluid

temperature decreases,thus lowering the Rankaine cycle efficiency.Multiple

pressure systems could recover more energy but add to the complexity of

the system and cost.Note however as the inlet gas temperature increases,say

to 1000 F,the difference in the amount of energy recovered between steam-water

system and ammonia-water system reduces significantly.This can be seen

by analyzing the gas temperature profiles for the two cases.The exit gas

temperatures for the two cases will be comparable and not so wide apart

as in the 550 F case.

Gas

turbine based combined cycles using this concept have 2-3 % higher efficiency

over multi-pressure combined cycle plants using steam/water as the working

fluid. In low gas temperature heat recovery systems such as diesel engine

exhaust or fired heater exhaust,the energy recovered from the hot gas stream

is more significant and Kalina cycle output increases by 20-30 %.The

main reason for the improvement is that the boiling of ammonia-water mixture

occurs over a range of temperatures,unlike steam and hence the amount of

energy recovered from the gas stream is much higher. See Figure below,where

a 550 F gas temperature source is shown with say a cold end fluid temperature

of 100 F. 70 % ammonia-water mixture at 500 psia by virtue of its varying

boiling point,is able to "match" or run parallel to the gas temperature

line while recovering energy and hence the exit gas temperature can be

as low as 200 F.The steam-water mixture at 500 psia,on the other hand,due

to pinch,approach point limitations and a constant boiling point of 467

F,cannot cool the gases below about 500 F.Only about 15-20 % of the energy

is recovered,compared to 100% in Kalina cycle.This can also be easily be

seen using the HRSG simulation software for gas turbine-steam systems developed

by the author(see my Homepage). Hence a lot of energy is wasted. By decreasing

the steam pressure,more energy could be recovered;however,the average fluid

temperature decreases,thus lowering the Rankaine cycle efficiency.Multiple

pressure systems could recover more energy but add to the complexity of

the system and cost.Note however as the inlet gas temperature increases,say

to 1000 F,the difference in the amount of energy recovered between steam-water

system and ammonia-water system reduces significantly.This can be seen

by analyzing the gas temperature profiles for the two cases.The exit gas

temperatures for the two cases will be comparable and not so wide apart

as in the 550 F case.

The

condensation of ammonia-water also occurs over a range of temperatures

and hence permits additional heat recovery in the condensation system,unlike

Rankaine cycle,where the low end temperature(affected by ambient conditions)

limits the condenser back pressure and power output of system.If the cooling

water temperature is say 100 F,less power is generated by the steam turbine

compared to say 40 F cooling water.The condenser pressure can be much higher

in Kalina cycle,and the cooling water temperatures do not impact the power

output of the turbine as in Rankaine cycle.Thermo-physical properties of

ammonia-water mixture can also be altered by changing the concentration

of ammonia.This helps to recover energy in the condensation system.Modifications

to the condensing system are also possible by varying the ammonia concentration

and thus more energy can be recovered from the exhaust gases.

The

condensation of ammonia-water also occurs over a range of temperatures

and hence permits additional heat recovery in the condensation system,unlike

Rankaine cycle,where the low end temperature(affected by ambient conditions)

limits the condenser back pressure and power output of system.If the cooling

water temperature is say 100 F,less power is generated by the steam turbine

compared to say 40 F cooling water.The condenser pressure can be much higher

in Kalina cycle,and the cooling water temperatures do not impact the power

output of the turbine as in Rankaine cycle.Thermo-physical properties of

ammonia-water mixture can also be altered by changing the concentration

of ammonia.This helps to recover energy in the condensation system.Modifications

to the condensing system are also possible by varying the ammonia concentration

and thus more energy can be recovered from the exhaust gases.

Expansion

in turbine gives a saturated vapor in Kalina cycle compared to wet steam

in Rankaine cycle,which requires protection of blades in the last few stages.Also

due to the higher pressure of vapor and lower specifc volume,the exhaust

system size can be smaller compared to steam.For example the specific volume

of a 70% ammonia-water mixture exhausting from a turbine at its dew point

of 240 F is 5.23 ft3/lb,while steam at its condensing temperature

of 70 F(sat pres=0.36 psia) has 868 ft3/lb.Thus the equipment

size can be smaller with Kalina system.

Expansion

in turbine gives a saturated vapor in Kalina cycle compared to wet steam

in Rankaine cycle,which requires protection of blades in the last few stages.Also

due to the higher pressure of vapor and lower specifc volume,the exhaust

system size can be smaller compared to steam.For example the specific volume

of a 70% ammonia-water mixture exhausting from a turbine at its dew point

of 240 F is 5.23 ft3/lb,while steam at its condensing temperature

of 70 F(sat pres=0.36 psia) has 868 ft3/lb.Thus the equipment

size can be smaller with Kalina system.

Conventional

equipment such as steam turbines and HRSGs can be used in Kalina cycle.The

molecular weight of ammonia and water are similar,17 and 18.

Conventional

equipment such as steam turbines and HRSGs can be used in Kalina cycle.The

molecular weight of ammonia and water are similar,17 and 18.

Since

the boiling point is varying,once through type HRSGs are used in kalina

systems.Carbon steel tubes are adequete. Extended surfaces may be used

if the gas stream is clean. For more information on Kalina cycle contact

Exergy Corp,California.

Click

here for Ganapathy's Homepage(Books,Articles and Software on Boilers,HRSGs)

email Ganapathy