High

Temperature Corrosion Problems in Waste

Heat Boilers

V.Ganapathy

One

of the problems with heat recovery boilers behind incinerators of solid,liquid

or municipal solid wastes is high temperature corrosion associated with

the formation of complex eutectics which have a low melting point and deposit

as slag on boiler heating surfaces.This is difficult to get rid of and

results in high temperature corrosion,fouling problems and consequent

higher exit gas temperature from the boiler and consequent lower steam

generation.Another concern in these applications is the presence of corrosive

gases such as chlorine and hydrogen chloride,which corrode the boiler tubes,particularly

those operating above 800 F,resulting in tube thinning and failure.Chlorine

attacks steel even at 400 F-500 F.There are several aspects to the corrosion

mechanism.Low

temperature corrosion problems in boilers are discussed elsewhere.

High

temperature liquid phase corrosion is caused by molten alkali metal salts

such as metal chlorides and their eutectics having a low melting point-see

table below.Slag thus formed attacks the protective iron oxide layer and

in course of time eats away the base tube material. In addition several

non-ferrous salts are formed with chlorine,which also have very low melting

points.These also deposit on low temperature surfaces such as evaporator

tubes and corrode them. By reducing the gas temperature to convection sections

below the melting points of these salts, one can minimize the slagging

concerns.However this may not not be always economically viable as a very

large radiant furnace would be needed in some cases.

High

temperature liquid phase corrosion is caused by molten alkali metal salts

such as metal chlorides and their eutectics having a low melting point-see

table below.Slag thus formed attacks the protective iron oxide layer and

in course of time eats away the base tube material. In addition several

non-ferrous salts are formed with chlorine,which also have very low melting

points.These also deposit on low temperature surfaces such as evaporator

tubes and corrode them. By reducing the gas temperature to convection sections

below the melting points of these salts, one can minimize the slagging

concerns.However this may not not be always economically viable as a very

large radiant furnace would be needed in some cases.

Corrosion

also occurs due to a non-uniform furnace atmosphere caused by partial oxidation,which

results in a reducing environment in which CO and H2S are produced.These

gases react with the protective layer of iron oxide formed on the tubes

exposing them to a corrosive attack. This situation is common in MSW plants.

Corrosion

also occurs due to a non-uniform furnace atmosphere caused by partial oxidation,which

results in a reducing environment in which CO and H2S are produced.These

gases react with the protective layer of iron oxide formed on the tubes

exposing them to a corrosive attack. This situation is common in MSW plants.

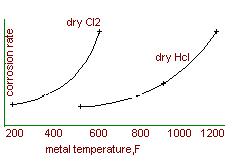

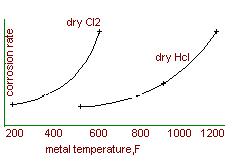

Corrosion

due to the presence of hydrogen chloride is severe at higher metal temperatures

as shown in the figure below.When plastic compoundsare incinerated,hydrogen

chloride vapors are formed as also chlorine.Chlorine attacks steel at low

temperatures.Hydrogen chloride attacks surfaces operating at high tube

wall temperatures,say above 800-850 F,such as superheater tubes.Using high

chromium,nickel alloys or stainless steels may reduce the corrosion rate

but failure of these tube surfaces is likely over the long haul.There are

examples of superheaters operating at 900-1000 F in MSW applications which

had to be replaced every few months!

Corrosion

due to the presence of hydrogen chloride is severe at higher metal temperatures

as shown in the figure below.When plastic compoundsare incinerated,hydrogen

chloride vapors are formed as also chlorine.Chlorine attacks steel at low

temperatures.Hydrogen chloride attacks surfaces operating at high tube

wall temperatures,say above 800-850 F,such as superheater tubes.Using high

chromium,nickel alloys or stainless steels may reduce the corrosion rate

but failure of these tube surfaces is likely over the long haul.There are

examples of superheaters operating at 900-1000 F in MSW applications which

had to be replaced every few months!

Table: Melting Point of a few Eutectics

| components |

melting

points,F |

| P2O3 |

1056 |

| 0.5Nacl-0.26Na2So4-0.24Na2Co3 |

1134 |

| 0.65

Na2So4-0.35 NaCl |

1163 |

| 0.62

Na2Co3-0.38Nacl |

1172 |

| NaCl |

1474 |

| Na2So4 |

1623 |

| Ca2O |

2257 |

| Fe2O3 |

2664 |

Minimizing

the Corrosion Concerns

There

are a few steps that can be taken by the boiler designer to minimze

these slagging problems and consequent corrosion; however they cannot be

completely eliminated.

Ensure

that the gases entering the convection section are cooled adequetely. Thiscan

be accomplished by using a large radiant furnace section.However this is

expensive and makes the boiler design more complicated.

Ensure

that the gases entering the convection section are cooled adequetely. Thiscan

be accomplished by using a large radiant furnace section.However this is

expensive and makes the boiler design more complicated.

Flue

gas recirculation could be used to recirculate and mix cool gases from

the boiler exit with the hot incoming gases,thus reducing the gas inlet

temperature to the boiler.However this increases the mass flow through

the boiler and hence its initial cost.Operating costs are increased by

using the recirculation fan.

Flue

gas recirculation could be used to recirculate and mix cool gases from

the boiler exit with the hot incoming gases,thus reducing the gas inlet

temperature to the boiler.However this increases the mass flow through

the boiler and hence its initial cost.Operating costs are increased by

using the recirculation fan.

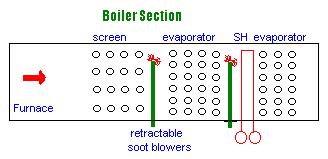

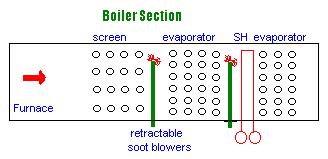

Since

hydrogen chloride corrosion rate increases signiifcantly beyond 800 F(even

high chromium,nickel steels have failed in due course),the boiler steam

parameters may be selected with care. Instead of say going for 1000 psig,1000

F steam,one may consider 600 psig,650 F steam,which results in lower superheater

tube wall temperatures and hence increases its life.It is also suggested

that the design have a slag screen section,with wide spaced tubes to prevent

accumulation of slag,followed by evaporator tubes and then the superheater

as shown above. This will increase the cost of the superheater (due to

the lower log-mean temperature difference) but will increase its life and

save on maintenance/replacement costs.Use of retractable soot blowers at

the hot end is suggested,while rotary blowers may be used at cooler ends.

Some designs use rapping mechanisms to shake off the dust and deposits.

Since

hydrogen chloride corrosion rate increases signiifcantly beyond 800 F(even

high chromium,nickel steels have failed in due course),the boiler steam

parameters may be selected with care. Instead of say going for 1000 psig,1000

F steam,one may consider 600 psig,650 F steam,which results in lower superheater

tube wall temperatures and hence increases its life.It is also suggested

that the design have a slag screen section,with wide spaced tubes to prevent

accumulation of slag,followed by evaporator tubes and then the superheater

as shown above. This will increase the cost of the superheater (due to

the lower log-mean temperature difference) but will increase its life and

save on maintenance/replacement costs.Use of retractable soot blowers at

the hot end is suggested,while rotary blowers may be used at cooler ends.

Some designs use rapping mechanisms to shake off the dust and deposits.

[A

similar design approach is suggested while firing heavy residual fuel oils

in steam generators. Radiant superheaters fail often due to the formation

of deposits of sodium,vanadium salts and their corrosive effect at high

temperatures. A buried convective superheater as shown above will be a

better choice in the long run as the superheater operates in a 300-500

F lower gas temperature region.Retractable soot blowers with wide access

lanes are also suggested as shown above for removing the deposits as soon

as they are formed. Rotary soot blowers have limited blowing energy and

may be used in the cooler gas regions where slag formation is minimal.]

Fire

tube boilers have limited flexibility compared with water tube boilers

when it comes to handling hot slag laden,corrosive gases.It is difficult

to clean the front end of the tube sheet.Though the boiler may be less

expensive compared to a water tube design,the author suggests that a throrough

review be made before selecting the cheap option,which can result in headaches

for the plant operating and maintenance personnel.

Fire

tube boilers have limited flexibility compared with water tube boilers

when it comes to handling hot slag laden,corrosive gases.It is difficult

to clean the front end of the tube sheet.Though the boiler may be less

expensive compared to a water tube design,the author suggests that a throrough

review be made before selecting the cheap option,which can result in headaches

for the plant operating and maintenance personnel.

In

hydrogen or ammonia plants,where process gas streams(containing methane,carbon

monoxide,carbon dioxide,hydrogen,water vapor at high gas pressure) generate

steam in waste heat boilers,hydrogen embrittlement is a concern. The absorption

of hydrogen into the metal results in loss of its ductility and failures

are likely at higher tube wall temperatures due to formation of methane

when hydogen reacts with carbon in the steel. Increasing the chromium content

of the steel(using T11,T22 material for the boiler tubes) helps to minimize

some of these concerns,as the low-chromium alloys help form stable carbides.

The Nelson's chart(see my book on waste Heat Boilers)gives an idea of the

chromium content to be used as a function of partial pressure of

hydrogen and tube temperature.Metal dusting concerns which also arise in

these boilers are minimized by use of low-chromium alloy steels.

In

hydrogen or ammonia plants,where process gas streams(containing methane,carbon

monoxide,carbon dioxide,hydrogen,water vapor at high gas pressure) generate

steam in waste heat boilers,hydrogen embrittlement is a concern. The absorption

of hydrogen into the metal results in loss of its ductility and failures

are likely at higher tube wall temperatures due to formation of methane

when hydogen reacts with carbon in the steel. Increasing the chromium content

of the steel(using T11,T22 material for the boiler tubes) helps to minimize

some of these concerns,as the low-chromium alloys help form stable carbides.

The Nelson's chart(see my book on waste Heat Boilers)gives an idea of the

chromium content to be used as a function of partial pressure of

hydrogen and tube temperature.Metal dusting concerns which also arise in

these boilers are minimized by use of low-chromium alloy steels.

Corrosion

is a complex subject and simple generic solutions cannot be dispensed through

papers or articles . Each case has to be evaluated on its merit and corrosion

consultants should be contacted for specfic problems. The article only

suggests a few thoughts,potential concerns and solutions from boiler design

view point.

Books,software,articles

on boilers,hrsgs(Ganapathy's Home Page)

email Ganapathy