UNDERSTANDING

HRSG TEMPERATURE PROFILES by V.Ganapathy

This article discusses the significance of pinch and approach points

in gas turbine Hrsgs. Unlike conventional steam generators,where

the inlet gas temperatures are very high,namely adiabatic combustion temperatures

of the fuel fired(3200-3400 F),the gas turbine exhaust inlet gas temperature

to the Hrsg is very low,on the order of 850-1000 F. This creates a problem.

We cannot arbitrarily assume an exit gas temperature to determine the steam

flow.In steam generators for example,if the feed water temperature is say

240 F,an exit gas temperature of 300 to 350 F is feasible. There are a

few reasons for this,such as the low ratio of gas/steam and capacity of

heat sink in the form of economizer.A lot of energy is transferred to the

steam before the flue gases enter the economizer,while in Hrsgs,it could

be very small due to the low inlet gas temperature.This in turn affects

the energy absorbed in economizer and hence the Hrsg exit gas temperature.Hence

gas/steam profiles cannot be easily predicted.If we arbitrarily assume

an exit gas temperature,we can get into either a

temperature cross situation(explained later) or the economizer could

be steaming. Hence the right way is to determine the steam generation and

gas/steam profiles using pinch and approach points

This article discusses the significance of pinch and approach points

in gas turbine Hrsgs. Unlike conventional steam generators,where

the inlet gas temperatures are very high,namely adiabatic combustion temperatures

of the fuel fired(3200-3400 F),the gas turbine exhaust inlet gas temperature

to the Hrsg is very low,on the order of 850-1000 F. This creates a problem.

We cannot arbitrarily assume an exit gas temperature to determine the steam

flow.In steam generators for example,if the feed water temperature is say

240 F,an exit gas temperature of 300 to 350 F is feasible. There are a

few reasons for this,such as the low ratio of gas/steam and capacity of

heat sink in the form of economizer.A lot of energy is transferred to the

steam before the flue gases enter the economizer,while in Hrsgs,it could

be very small due to the low inlet gas temperature.This in turn affects

the energy absorbed in economizer and hence the Hrsg exit gas temperature.Hence

gas/steam profiles cannot be easily predicted.If we arbitrarily assume

an exit gas temperature,we can get into either a

temperature cross situation(explained later) or the economizer could

be steaming. Hence the right way is to determine the steam generation and

gas/steam profiles using pinch and approach points

Table of suggested Pinch and Approach points

| item |

pinch

point , F |

approach

point,F |

| evaporator type |

bare

finned |

|

| inlet gas temp,F |

|

|

| 1200-1800 |

130-150

30-60 |

40-70 |

| 700-1200 |

80-130

10-30 |

10-40 |

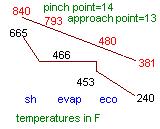

As shown in the figure above,pinch point is the difference between the gas

temperature leaving the evaporator and the saturation temperature,while

approach point is the difference between the water temperature leaving

the economizer and saturation temperature. If these values are reasonably

assumed,then we obtain a thermodynamically feasible temperature profile.

Pinch and approach points are to a great extent dependent on the inlet

gas temperature and whether the evaporator is bare or finned.These values

are shown in the table above and are based on the author's experience.

For example in incineration plants,the gas inlet temperature could be 1600

F. Here we cannot assume a pinch point of 20 F and approach of 20 F as

it will lead to an exit gas temperature below the feed water temperature.This

is explained below!.Also,with bare tubes,if we go for a small pinch point,the

module size becomes too large. In typical gas turbine Hrsgs using finned

evaporators,10-30 F pinch and approach points are reasonable and can be

achieved in the unfired mode.

FACTS ABOUT PINCH AND APPROACH POINTS

Pinch and approach points are selected in unfired mode at "Design"

gas flow,inlet gas temperature conditions.Once they are assumed,the surface

areas of the Hrsg evaporator,superheater and economizer are indirectly

fixed or considered selected .

Once selected,pinch and approach will vary with other conditions of

gas flow,steam parameters. That is,we select pinch and approach only once

and in other "Off-Design cases",we have to use an iterative procedure to

arrive at the gas/steam temperature profiles and steam generation.The HRSG simulation program does just that.

Pinch and approach shuld be selected in the unfired gas turbine mode(even

if the Hrsg operates in fired mode) and preferably at the lowest inlet

gas temeprature to avoid steaming in the economizer(discussed later).If

they are selected in the fired mode,we have to perform a number of calculations

to check if the steam temperature can be achieved in the unfired mode,whether

the economizer does not steam in unfired mode etc.

WHY HRSG EXIT GAS TEMPERATURES CANNOT BE ASSUMED

Some engineers with little experience in gas turbine Hrsg performance

aspects assume an exit gas temperature and compute the steam generation

without going through the pinch,approach point calculations. This can lead

to problems as discussed below.

Neglecting heat loss and blow down for simplicity and considering the

superheater and evaporator in the figure above ,we have:

WgxCpgx(tg1-tg3)=Wsx(hs2-hw2)

(1)

considering the entire Hrsg,

WgxCpgx(tg1-tg4)=Wsdx(hs2-hw1)

(2)

where Wg,Ws are the gas and steam flow,lb/h

hs2,hw2,hw1 are the enthalpies of

final steam,water leaving and entering economizer,btu/lb

Dividing (1) by (2) and neglecting variations in specific heat Cpg:

(tg1-tg3)/(tg1-tg4)=(hs2-hw2)/(hs2-hw1)

= K (3)

Note that K is a function of steam and water parameters only.

For steam generation to occur and for a thermodynamically feasible

temperature profile,two conditions must be met: tg3>ts,ts being

saturation temperature and tg4>tw1.If pinch and approach

are arbitrarily selected,it is likely one of them can fail.Hence all these

values are intimately related. Table below shows typical K values and exit

gas temperatures at various pressures.

EFFECT OF STEAM PARAMETERS

ON EXIT GAS TEMPERATURE

| press,psig |

steam temp,F |

sat temp,F |

K |

exit gas temp,F |

| 100 |

338 |

338 |

0.904 |

300 |

| 150 |

366 |

366 |

0.8754 |

313 |

| 250 |

406 |

406 |

0.8337 |

332 |

| 400 |

448 |

448 |

0.7895 |

353 |

| 400 |

600 |

450 |

0.8063 |

367 |

| 600 |

490 |

490 |

0.74 |

373 |

| 600 |

750 |

492 |

0.7728 |

398 |

[basis: pinch point=20 F,approach point=15 F,inlet gas=900 F,feed water=230

F]

The following points may be noted:

1.As steam pressure and steam temperature increase,the exit gas temperature

increases. That is,we cannot get 300 F exit gas when generating 600 psig,750

F steam! Hence the purpose of Hrsg simulation is to arrive at the proper

gas/steam profiles and steam generation. I have seen several specifciations

written by consultants,where a 300 F economizer exit gas temperature is

specified in a high pressure system. If one computes steam generation

based on 300 F exit gas,he will be in a rude shock as 300 F cannot be thermodynamically

achieved at high pressures!

2.Why can't we get 300 F exit gas at 600 psig,750 F steam conditions?

K=0.7728 Let us try to compute tg3 from tha

above equation for K.

0.7728=(900-tg3)/(900-300) or tg3=436 F,which

is below the saturation temperature of 492 F.This is called Temperature

Cross!!

3.What should be done to achieve 300 F in the above case?

Increase tg1 by supplementary firing. say tg1=1600 F. Then

(1600-tg3)/(1600-300)=0.7728 or tg3=595 F. pinch

point=(595-492)=103 F. Note that as inlet gas temperature increases the

pinch point increases and the exit gas temperature decreases.This aspect

was discussed in the article on Generating

steam efficiently in cogeneration plants .

4.Let us say that at 1600 F gas inlet someone selected 20 F pinch.What

happens?

tg3=492+20=512 F

(1600-512)/(1600-tg4)=0.7728 or tg4=192 F,which

is below the feed water temperature of 230 F and hence not feasible if

the approach point were 20 F. So let us calculate what should be the approach

point.

At 600 psig,750 F,hs2=1379 btu/lb. hw1=200 btu/lb.

K=(1600-512)/(1600-1300)=0.836 or hw2=393 btu/lb. This corresponds

to a water temperature of 416 F or an approach point of 76 F. This is the

reason we select pinch and approach in unfired modes as we have no clue

as to the exit gas temperature or pinch point or approach point in fired

conditions!

Now in order to estimate the correct gas/steam temperature profile we first obtain the steam flow from equation(1)above.All other variables are known except steam flow. Then using (2),the exit gas temperature is found.This is the "DESIGN" profile.The HRSG

simulation program may be used to determine the steam generation,temperature

profiles in unfired "Design" as well as in unfired,fired "Off-Design" conditions for complex Hrsgs.

Boilers,HRSGS,Steam

Plant Calculations

Boilers,HRSGS,Steam

Plant Calculations

email

Ganapathy

email

Ganapathy

This article discusses the significance of pinch and approach points

in gas turbine Hrsgs. Unlike conventional steam generators,where

the inlet gas temperatures are very high,namely adiabatic combustion temperatures

of the fuel fired(3200-3400 F),the gas turbine exhaust inlet gas temperature

to the Hrsg is very low,on the order of 850-1000 F. This creates a problem.

We cannot arbitrarily assume an exit gas temperature to determine the steam

flow.In steam generators for example,if the feed water temperature is say

240 F,an exit gas temperature of 300 to 350 F is feasible. There are a

few reasons for this,such as the low ratio of gas/steam and capacity of

heat sink in the form of economizer.A lot of energy is transferred to the

steam before the flue gases enter the economizer,while in Hrsgs,it could

be very small due to the low inlet gas temperature.This in turn affects

the energy absorbed in economizer and hence the Hrsg exit gas temperature.Hence

gas/steam profiles cannot be easily predicted.If we arbitrarily assume

an exit gas temperature,we can get into either a

temperature cross situation(explained later) or the economizer could

be steaming. Hence the right way is to determine the steam generation and

gas/steam profiles using pinch and approach points

This article discusses the significance of pinch and approach points

in gas turbine Hrsgs. Unlike conventional steam generators,where

the inlet gas temperatures are very high,namely adiabatic combustion temperatures

of the fuel fired(3200-3400 F),the gas turbine exhaust inlet gas temperature

to the Hrsg is very low,on the order of 850-1000 F. This creates a problem.

We cannot arbitrarily assume an exit gas temperature to determine the steam

flow.In steam generators for example,if the feed water temperature is say

240 F,an exit gas temperature of 300 to 350 F is feasible. There are a

few reasons for this,such as the low ratio of gas/steam and capacity of

heat sink in the form of economizer.A lot of energy is transferred to the

steam before the flue gases enter the economizer,while in Hrsgs,it could

be very small due to the low inlet gas temperature.This in turn affects

the energy absorbed in economizer and hence the Hrsg exit gas temperature.Hence

gas/steam profiles cannot be easily predicted.If we arbitrarily assume

an exit gas temperature,we can get into either a

temperature cross situation(explained later) or the economizer could

be steaming. Hence the right way is to determine the steam generation and

gas/steam profiles using pinch and approach points