| Designing Steam Generators for both High and Low Steam Pressure Operation - V.Ganapathy |  |

| item | low pressure | high pressure(future) |

| max steam flow,lb/h | 175,000 | 175,000 |

| steam temperature,F | 680 | 760 |

| steam pressure,psig | 150 | 650 |

| pressure drop,psi | 23 | 46 |

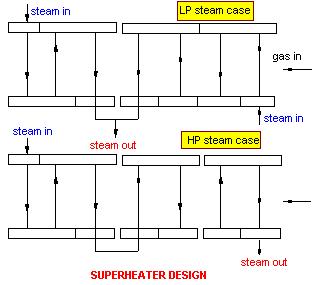

Design of Superheater

|

The

steam generator is a packaged D type boiler with a buried superheater design,located

behind several rows of screen tubes. This convective design has several

advantages over a radiant design as discussed in the article Convective

Superheaters vs Radiant. Initially when low pressure steam is generated,the

steam flow is split up into two paths,one stream entering the superheater

at one end and another at the other,in mixed flow fashion as shown. There

are 24 streams (parallel paths) obtained by baffling the headers and this

is unchanged at high pressure operation also. The flow in each path balances

out depedning on the pressure drops in each section. The final steam mixes

and exits at the middle as shown.The steam inlet,outlet have 2-10 in pipes.

Note also

that the path traversed by the steam is much smaller compared to that in

the high pressure case and hence the lower pressure drop.In the future

case of high pressure operation,1-10 in pipe for inlet and outelet and

the steam enters and leaves the superheater in counter flow fashion as

shown. The number of superheater streams is still 24 and due to the

lower specific volume,twice the flow passes through the same streams.The

pressure drops,tube wall temperatures were all checked at the various modes,

low loads and turn down conditions.

The steam check valve size was also changed to 1- 8 in from 2-10 in pipes.Since the specific volume of water does not change much with pressure,the feed line sizes,valves were unchanged.The steam generator has been in operation for several years. |

Articles,Books,Software

on Boilers,HRSGs(V.Ganapathy's home page )

email Ganapathy