APPLICATIONS FOR COILS PROGRAM

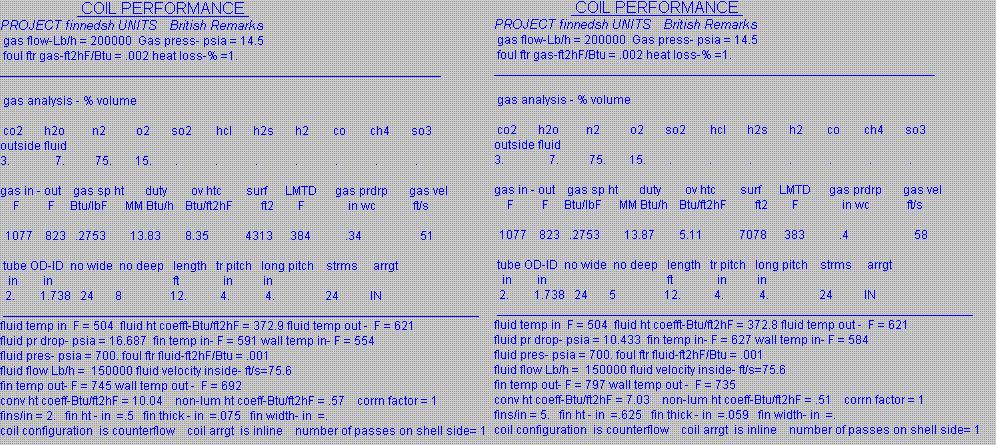

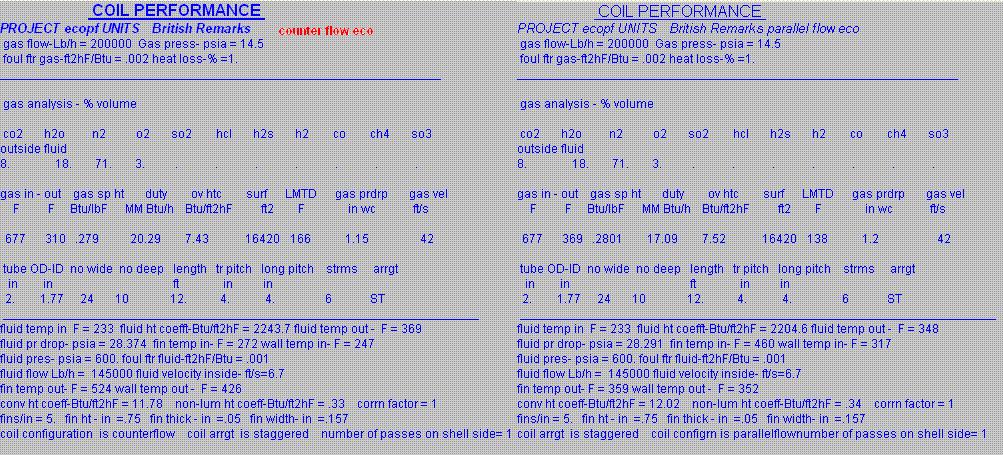

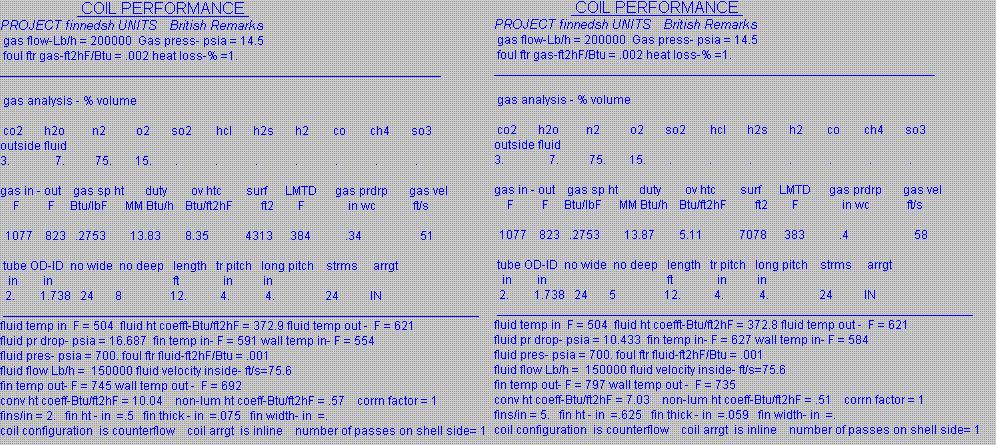

The first example shows the effect of using a large fin density in a superheater. The heat flux inside the tubes increases and hence the tube wall and fin tip temperatures increase, though the duty is the same in both cases.Also look at the difference in surface area for the same duty! One can be misled by large differences in surface areas thinking more the surface,better the design..BUT IT IS NOT SO WITH FINNED TUBES IN PARTICULAR as heat transfer coefficient decreases with increase in fin surface area. The second example shows what happens to the same economizer when used in parallel versus counter flow arrangement. See the differences in gas exit temperature and duty for the same coil and gas inlet conditions! The COILS program may be used to check a new design or see what happens to an existing coil when gas or steam or water conditions change. It can also check if fouling has occurred.If from the program you get say 350 F as exit gas temperature and in operation you see 375 F, then fouling may be the cause