Advantages

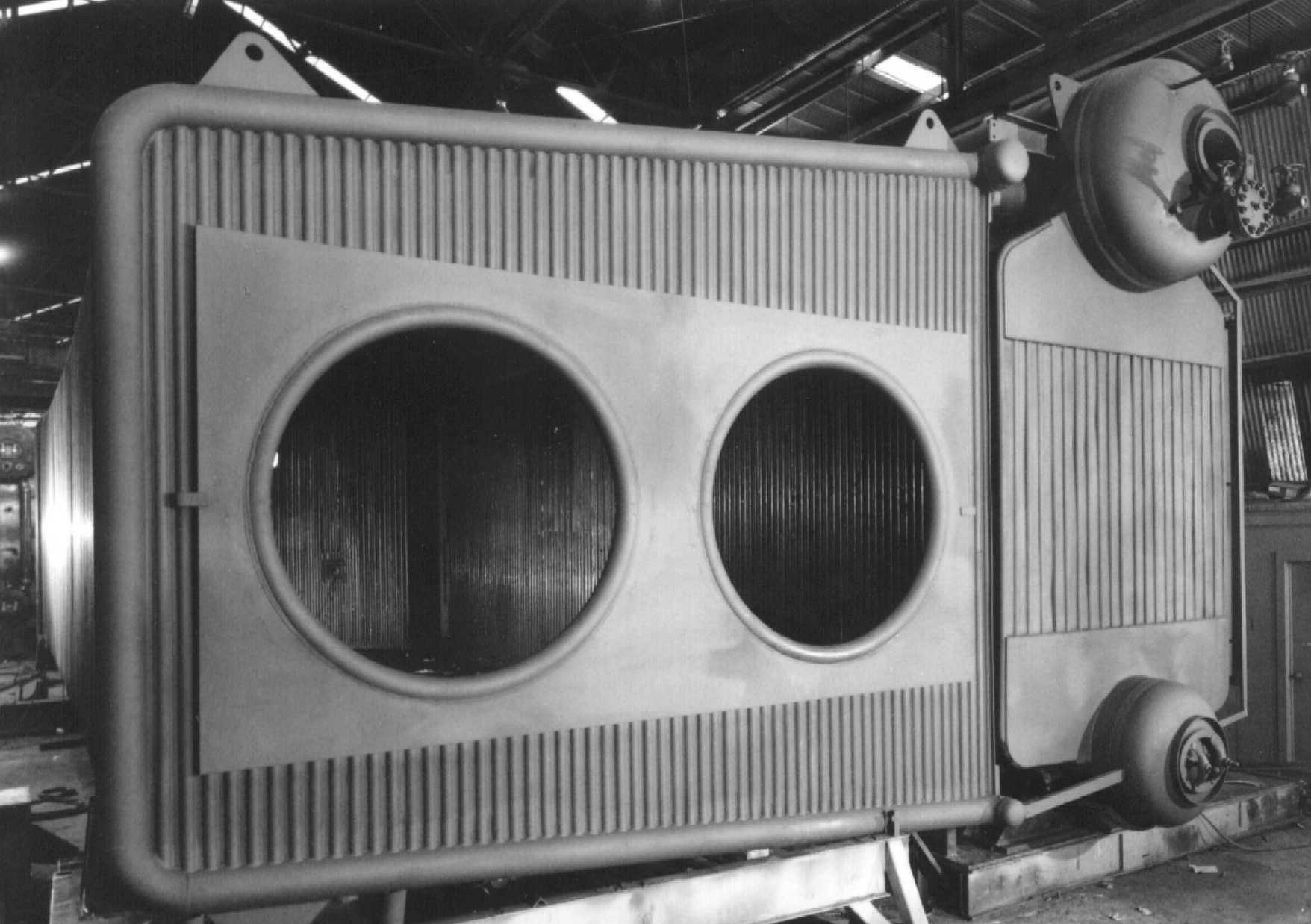

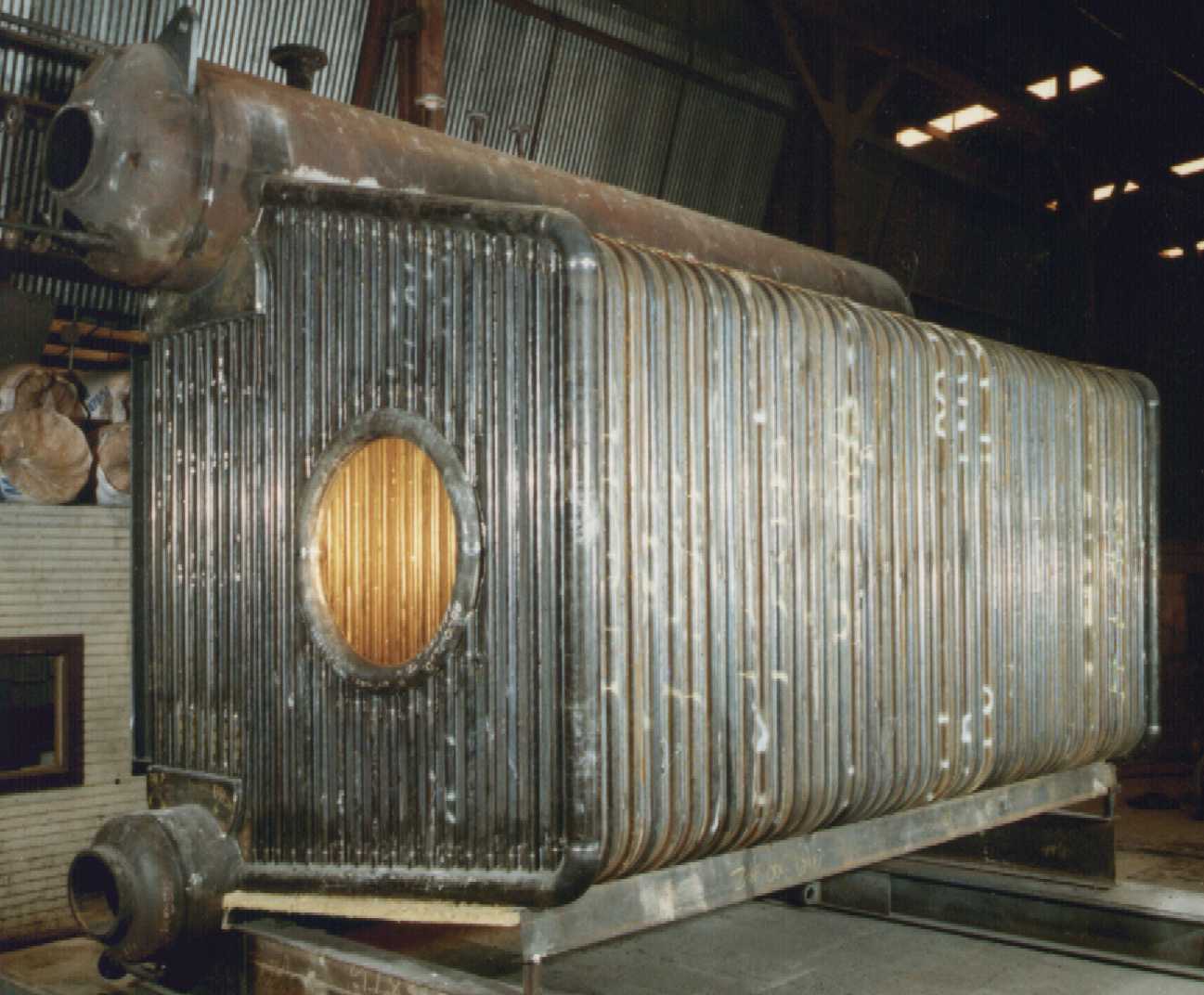

of ABCO Water cooled Furnaces

One

of the recent improvements in packaged boiler design is the water cooled

furnace that offers several advantages over refractory lined furnaces.

The furnace side walls,front and rear walls and floor are of membrane wall

construction.This results in a leak proof enclosure,eliminating gas leakage

and corrosion of casing as seen in boilers with refractory. One

of the recent improvements in packaged boiler design is the water cooled

furnace that offers several advantages over refractory lined furnaces.

The furnace side walls,front and rear walls and floor are of membrane wall

construction.This results in a leak proof enclosure,eliminating gas leakage

and corrosion of casing as seen in boilers with refractory.

Refractory

maintenance concerns are eliminated. Plant engineers are familiar with

the annual cost of refractory maintenance and the associated downtime. Refractory

maintenance concerns are eliminated. Plant engineers are familiar with

the annual cost of refractory maintenance and the associated downtime.

Startup

rates can be faster without concern for refractory limited heat up rates

and hence fuel cost per startup is also reduced.The entire furnace expands

and contracts as a unit. This eliminates relative expansion problems that

occur between water cooled walls and refractory lined casings. Startup

rates can be faster without concern for refractory limited heat up rates

and hence fuel cost per startup is also reduced.The entire furnace expands

and contracts as a unit. This eliminates relative expansion problems that

occur between water cooled walls and refractory lined casings.

For

a given volume,the ABCO design has lower heat release rates on area basis

due to the larger furnace effective projected area; hence heat fluxes are

lower. Depending on the furnace dimensions,the improvement can be 5 to

15 %.The furnace exit gas temperature is also lower. For

a given volume,the ABCO design has lower heat release rates on area basis

due to the larger furnace effective projected area; hence heat fluxes are

lower. Depending on the furnace dimensions,the improvement can be 5 to

15 %.The furnace exit gas temperature is also lower.

Cooling

of the flame and reradiation from refractory impact local combustion temperatures

and hence NOx formation.The contribution to NOx from the front refractory

lined wall is signifcant .A cool environment at the flame front due to

the water cooled front wall design,on the other hand, helps to lower the

emissions. Cooling

of the flame and reradiation from refractory impact local combustion temperatures

and hence NOx formation.The contribution to NOx from the front refractory

lined wall is signifcant .A cool environment at the flame front due to

the water cooled front wall design,on the other hand, helps to lower the

emissions.

Refractory

on the floor is another design feature which has been carried over from

the last generation of boiler designs.There is no need for it.The

effective furnace projected area is reduced,increasing the furnace exit

gas temperature,thereby causing problems for the superheater if present,in

addition to increasing the redradiation from the floor which increases

the NOx.There are hundreds of boilers designed without floor refractory,which

are working fine.The problems in oil fired furnaces due to higher furnace

exit gas temperature can be more severe,such as possible slagging and corrosion

of superheaters. Refractory

on the floor is another design feature which has been carried over from

the last generation of boiler designs.There is no need for it.The

effective furnace projected area is reduced,increasing the furnace exit

gas temperature,thereby causing problems for the superheater if present,in

addition to increasing the redradiation from the floor which increases

the NOx.There are hundreds of boilers designed without floor refractory,which

are working fine.The problems in oil fired furnaces due to higher furnace

exit gas temperature can be more severe,such as possible slagging and corrosion

of superheaters. |