V.Ganapathy

|

Time

required to Heat Up Boilers

V.Ganapathy |

Flue gas at a temperature of Tg1 enters the evaporator(superheater/economizers not considered in this model),which is initially at a temperature of t.Then the transient heating of the boiler may be represented by the equations:

Mc dt/dz =WgCpg (Tg1-Tg2)(1-h) = UADT (1) where

Mc=

water equivalent of boiler(mass of steel x specific heat of steel + mass

of water x specific heat of water + mass of insulation x specific heat

of insulation).Include drums,tubes,casing.

dt/dz

= rate of change of boiler temperature , deg F/h

Wg

= gas flow,lb/h

Cpg

= gas specific heat,Btu/lbF

Tg1,Tg2

= boiler gas inlet and exit temperatures,F

U

= overall heat transfer coefficient,Btu/ft2hF

A

= surface area, ft2

t

= initial temperature of boiler system,F

z

= time for heating, h

DT

=log-mean temperature difference,F = (Tg1- t)-(Tg2

-t)/ ln[ (Tg1- t)/(Tg2 -t)]

(2)

h

= heat loss,fraction

Simplifying (1) and (2) we have:

ln[ (Tg1- t)/(Tg2 -t)] = UA/WgCpg (1-h) or

Tg2 = t + (Tg1 -t)/ e UA/WgCpg (1-h) = t + (Tg1-t)/K (3)

Substituting for Tg2 in (1),we have:

Mc dt/dz =WgCpg (Tg1-t)(1-h)(K-1)/K (4)

or

dt/(Tg1-t) = [WgCpg /Mc] (1-h)[(K-1)/K] dz (5)

Integrating between an initial temperature of t1 to t2,the time to heat up the boiler is given by:

ln[(Tg1-t1)/(Tg1-t2)] = [WgCpg /Mc] (1-h)[(K-1)/K] z (6)

The above equation gives an idea of the time required to heat up the boiler from a temperature of t1 to t2. Note that once the boiler is brought up to boiling conditions,additional terms must be used on the left hand side of equation (1) to consider steam generation and rate of pressure build up,which are not given here.

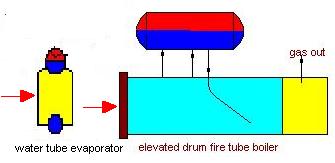

Example:A

water tube waste heat boiler of weight 50,000 lb and containing 30,000

lb of water is initially at 100 F. 130,000 lb/h of flue gases at 1400 F

enter the unit. Assume:

Gas

specific heat = 0.3 Btu/lbF

Steel

specific heat =0.12 Btu/lbF

Surface

area =21,000 ft2

Overall

heat transfer coefficient = 8 Btu/ft2hF

Estimate

the time to bring up the boiler to 212 F. Neglect casing heat loss .

Solution:

Estimate

K = e UA/WgCpg (1-h) = e (8x21,000/130,000/0.3)

= 74

Mc

=50,000x0.12 +30,000x1 = 36,000

From

(6),

ln[(1400-100)/(1400-212)] =0.09 = 130,000x0.3x73/(74x36,000)z or z = 0.084 h = 5.1 min