Evaluating

HRSG Field Data

V.Ganapathy

Evaluating

HRSG Field Data

V.Ganapathy

Gas

Turbine HRSGs like other waste heat boilers are designed for a particular

set of conditions but often operate at slightly or even significantly different

gas/steam parameters due to various reasons. The steam pressure could be

different due to plant header conditions;feed water temperature may be

5 to 15 F off due to deaerator operation;more steam could be taken off

the HRSG for deaeration; exhaust gas flow ,temperature and analysis could

be different due to changes in ambient conditions and gas turbine load

and so on..So how does then one reconcile the actual operating data with

the HRSG design data or guarantees?

HRSG

simulation or the HRSGS program could help in determining if the HRSG is

performing as designed even under different gas/steam parameters.This

will be explained using the case of a simple single pressure HRSG.

Example:A

gas turbine HRSG is designed for the parameters shown in Table 1. When

put into operation,the field data was slightly different as shown. The

steam temperature is uncontrolled.

Gas

analysis used :% vol co2=3,h2o=7,n2=75,o2=15.use a heat loss=1% in both

cases.The plant engineer wants to know if the HRSG is doing fine or not

and whether the lower steam generation is solely due to the lower gas flow/inlet

temperature conditions and steam pressure.

Table of design and operating data for HRSG

| condition |

Design/Guarantee |

Operation/test |

| gas

flow,lb/h |

550,000 |

? |

| exhaust

gas temperature,F |

1000 |

970 |

| exit

gas temperature,F |

371 |

380 |

| steam

pressure,psig |

600 |

500 |

| steam

temperature,F |

700 |

690 |

| feed

water temperature,F |

230 |

230 |

| blow

down,% |

2 |

0 |

| steam

flow,lb/h |

79,400 |

68,700 |

The above

situation is not uncommon in cogeneration plants.Let us use HRSGS,the HRSG

simulation program, to see how the HRSG is doing.

(Visit

the HRSG Simulation web site for a Free Demo and information on HRSG simulation)

The

HRSGS program is used to firm up or establish the HRSG 'design'. Using

the gas parameters given in the design case ,the pinch and approach points

are varied till we get the exit gas temperature close to the design value;the

design pinch and approach points are then frozen.The design is also indirectly frozen or established.If the water temperature

at the exit of the economizer is known,the approach point used can also

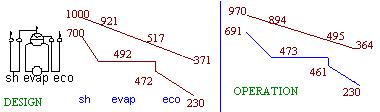

be verified.The output from the HRSGS program is shown below.

(The

temperatures are in F,gas/steam flows in lb/h and the duty in MM Btu/h

and steam pressure in psia.)

(The

temperatures are in F,gas/steam flows in lb/h and the duty in MM Btu/h

and steam pressure in psia.)

Design Case: Establishing the HRSG Design basis: gas flow=550,000 lb/h

| surface |

gas

in F |

gas

out |

stm

in |

stm

out |

duty |

press |

flow |

%

stm |

pinch |

apprch |

| suph |

1000 |

921 |

492 |

700 |

11.71 |

615 |

79440 |

100 |

|

|

| evap |

921 |

517 |

472 |

492 |

59.36 |

635 |

79440 |

100 |

25 |

20 |

| econ |

517 |

371 |

230 |

472 |

20.77 |

645 |

81029 |

|

|

|

In order

to evaluate the off-design or operating condition,the gas flow is first

determined from the operating data using heat balance methods. Gas flows

are difficult to measure,while gas temperatures,steam/water flows can be

measured more accurately.The energy absorbed by steam is first computed

and using the inlet and exit gas temperatures and the gas analysis,the

gas specific heat or enthalpy is computed from which the gas flow is obtained.

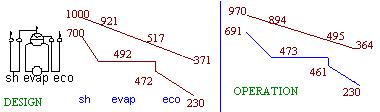

In this case,the gas flow can be shown to be 501,300 lb/h.With this gas flow,the HRSGS program is again run in the off-design

mode and the results are shown below.Note that the steam pressure

is different in the off-design case.

Off-Design

performance:Verifying the operating data: gas flow=501,300 lb/h

| surface |

gas

in F |

gas

out |

stm

in |

stm

out |

duty |

press |

flow |

%

stm |

pinch |

apprch |

| suph |

970 |

894 |

473 |

691 |

10.26 |

515 |

69524 |

100 |

|

|

| evap |

894 |

495 |

461 |

473 |

52.97 |

533 |

69524 |

100 |

22 |

12 |

| econ |

495 |

364 |

230 |

461 |

16.93 |

543 |

69524 |

|

|

|

In order

to arrive at some conclusion,the HRSG supplier and plant owner should agree

to some tolerances in instrument readings,errors in measurements,procedures

used for gathering data etc.The ASME PTC 4.4 gives some information on

these issues.

From

the off-design run,It can be seen that the HRSG should be generating 69,524

lb/h and that the gas exit temperature should be 364 F,while that measured

is higher and the steam flow is also lower.Hence there is reason to

investigate further as even after correcting for the different gas inlet

temperature,flow and steam pressure,the actual performance is off from

that suggested by the simulation process.It is possible that the HRSG

is not adequetely sized or that the steam flow readings,gas temperatures

have to be checked again.In any case,with the HRSGS program,plant engineers

have a tool for evaluating HRSG performance under different parameters

and operating conditions.One cannot simply say that due to differences

in steam pressure or gas flow or temperatures,the HRSG performance is different

from that guaranteed and walk away.HRSGS program also helps the plant engineer

to perform what-if analysis. Using one set of operating data,the performance

at other conditions may be obtained.Say in the future,the feed water temperature

or steam pressure is likely to be different or if the gas turbine is going

to be replaced,the HRSG performance can be easily evaluated using HRSGS

program.One can also see what happens if supplementary firing were to be

done.What is most important is that he can perform these studies himself

without contacting the HRSG supplier or use the HRSG supplied information

to verify his calculations and thus become a knowledgeable customer!

Note that the simulation process

is explained at my web site above and also in my books. One of the major

features,which makes this a simple process is that we don't have to know

the tube/fin configuration,geometry,tube lengths,spacings etc to perform

the above analysis! Hence anyone familiar with heat balances can do it!

[Note that we could have also established the design

using the operating data and then checked the off-design performance using

the guarantee gas inlet conditions and checked for the steam generation].

Note

that this is a simple HRSG configuration.Similar analysis could be

performed for complex,multi-pressure, fired HRSGs. The HRSG supplier and

Plant engineers have to work together and agree to several aspects discussed

above before reaching any drastic conclusions as there are lot of variables

involved.

Books,software,papers

on Boilers,HRSGs,Steam Plant calculations

email Ganapathy

Evaluating

HRSG Field Data

V.Ganapathy

Evaluating

HRSG Field Data

V.Ganapathy

(The

temperatures are in F,gas/steam flows in lb/h and the duty in MM Btu/h

and steam pressure in psia.)

(The

temperatures are in F,gas/steam flows in lb/h and the duty in MM Btu/h

and steam pressure in psia.)