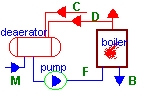

M,C,F,B

and D are the make up water flow,condensate returns,feed water flow,blow

down and deaeration steam ,all in lb/h.The calculation procedure for deaeration

steam is illustrated by an example.

M,C,F,B

and D are the make up water flow,condensate returns,feed water flow,blow

down and deaeration steam ,all in lb/h.The calculation procedure for deaeration

steam is illustrated by an example.

Example:A boiler generates 50,000 lb/h of saturated steam at 300 psia,out of which 10,000 lb/h is returned to the deaerator as condensate at 180 F.The rest is used in process.Make up water enters at 70F and steam at 300 psia is used for deaeration.The boiler drum water has a total dissolved solids(TDS) of 1500 ppm. The deaerator operates at 25 psia. The blow down also has a TDS of 1500 ppm,while the make up water has a TDS of 100 ppm.

Solution:From

mass balance around the deaerator:

10,000+D+M=F=50,000+B

(1)

From

energy balance around deaerator:

10,000x148+1202.8xD+Mx38=209xF=209x(50,000+B)

(2)

where

148,1202.8,38 and 209 are the enthalpies of condensate,boiler steam, make

up water and feed water respectively in btu/lb. These values are from steam

tables.

From

balance of total dissolved solids in the system:

100xM=1500xB

or M=15B

(3)

In

this equation,we are neglecting the TDS of condensate,which is as good

as steam and for practical purposes, negligible,as steam has a low level

of TDS,typically 0.5 to 1 ppm..

There

are three unknowns and three equations. From (1),

D+M=40,000

+B (4)

Substituting

(3) into (4),

D+15B=40,000+B

or D+14B=40,000

(5)

From

(2)

1,480,000+1202.8D+38x15B=209x50,000+209B

(6)

Solving

(5) and (6) we have:

B=2375,D=6750,M=35,625

and F=52,375 lb/h. Considering vent steam and other heat losses,the value

of D may be increased by 1 to 3 % for design purposes.

It

is seen that the boiler water quality and feed water quality play a dominant

role in deaeration steam evaluation. Larger the make up or higher the boiler

water TDS,more the deaeration steam.Blow down losses also will be high.Boiler

water quality is often maintained at levels suggested by either ABMA or

ASME guidelines on boiler water. Table below is an extract from these guidelines.

Table: Recommended Boiler water quality

| drum press,psig | per ASME | per ABMA |

| 0-300 | <3500(mmho/cm) | 700-3500(ppm) |

| 301-450 | <3000 | 600-3000 |

| 451-600 | <2500 | 500-2500 |

| 601-750 | <2000 | 200-1000 |

| 751-900 | <1500 | 150-750 |

| 901-1000 | <1000 | 125-625 |

Note that per ASME,the boiler water TDS is mentioned as specific conductance in micro mhos/cm,while the ABMA mentions the water quality in ppm. The relation between the two is about 0.45-0.5. That is, 1000 ppm=2000 mmho/cm.It can be seen that at lower steam pressures,up to 600 psig,the ASME is more stringent than the ABMA. Also,one may maintain the boiler water at lower levels than recommended and reduce the blow down.The drum internals has to be sized for achieving the desired steam purity based on boiler water quality. A few plants also operate at higher than recommended water quality. This affects not only the blow down quantity,which is a waste of energy,but also the performance of the drum internals and steam purity. In plants with superheaters,one has to be concerned with steam purity levels in addition to blow down water flow due to formation of deposits and assocated tube failure concerns. Investment in good feed water quality and drum internals goes a long way in reducing overall plant operating costs and maintenance downtime. Also,demineralized feed water is recommended if the feed water is used in spray attemperator for steam temperature control.

![]()