|

|||

|

|||

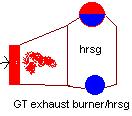

This

article reviews a simple approach namely the MM Btu method to evaluate

combustion air needs in steam generators and the oxygen consumption in

gas turbine HRSGs. The advantage is that no

deatiled calculations are required.

This

article reviews a simple approach namely the MM Btu method to evaluate

combustion air needs in steam generators and the oxygen consumption in

gas turbine HRSGs. The advantage is that no

deatiled calculations are required.

| Example

1

Let us calculate the amount of air per Mm Btu fired for fuel oil. Let C=87.5,H=.125 and deg API=28,a typical # 2 fuel oil. HHV is obtained from the formula: HHV=17887+57.5xdeg API-102.2S,where S=%sulfur. HHV=17887+57.5x28-102.2x0=19497 Btu/lb Amount of theoretical dry air in lb/lb fuel from above is: wa=11.53x0.875+34.34x0.125=14.38 lb/lb fuel. 1 MM Btu fuel fired requires (1x106/19497)=51.28 lb fuel Hence air required for 1 MM Btu fuel=51.28x14.38=737 lb Example 2 Take the case of natural gas with a volumetric fuel analysis:CH4=83.4,C2H6=15.8,N2=0.8 Converting to weight basis:% CH4=83.4x16/(83.4x16+15.8x30+.8x28)=72.89 similarly,C2H6 =25.89 and N2=1.22. Using the above formula,wa=17.265x0.7289+16.12x0.2589=16.75 lb/lb fuel HHV =0.7289x23876+0.2589x22320=23,181 Btu/lb. Combustion constants 23,876 and 22,320 were taken from tables available in books. The amount of fuel equivalent to 1 Mm Btu fired=1x106/23181=43.1 lb and air required for this amount=43.1x16.75=722 lb. Example 3 Take the case of 100% propane. 1 lb fuel requires 15.7 lb air from fundementals. 1 MM Btu fired has 1x106/21661=46.17 lb of propane. hence 1 MM Btu fired requires =46.17x15.7=725 lb air. |

Table

of combustion constants C

Blast furnace gas 575 Bagasse 650 CO gas 670 Refinery and oil gas 720 Natural gas 730 Furnace oil and lignite 745-750 Bituminous coals 760 Anthracite 780 Coke 800

C is air required in lb/MM Btu(HHV) |

Books,Software

on Boilers,Steam Plant calculations

email Ganapathy